Asset maintenance in a post-pandemic world.

The global electric utility industry has served its customers’ needs for over 100 years. During this time its success has relied on its ability to find new ways of operating in a constantly evolving world. As the industry grapples with the continued disruption caused by Covid19, the sector is facing yet another new challenge: asset maintenance in a post-pandemic world.

As society begins to tentatively emerge from lockdown, social distancing is likely to remain a long-lasting feature in our daily lives. Many continue to stay at home, but that’s not an option for the frontline workers running critical power transmission infrastructure and keeping the lights on.

Clearly, the biggest threat of the coronavirus is that to people. Every utility we have talked to has rightly placed priority on safeguarding their employees’ health and safety, minimizing people required onsite. Utilities must factor in reduced headcounts alongside the logistical challenges of maintaining social distancing among those at work.

How can utilities keep up with their power line inspection and maintenance regimes with a reduced onsite workforce, or a workforce who are based at home?

Taking back control with remote control!

Fortunately, these aren’t unsolvable problems. The pandemic has hit at a time where technology has progressed such that it can provide some solutions.

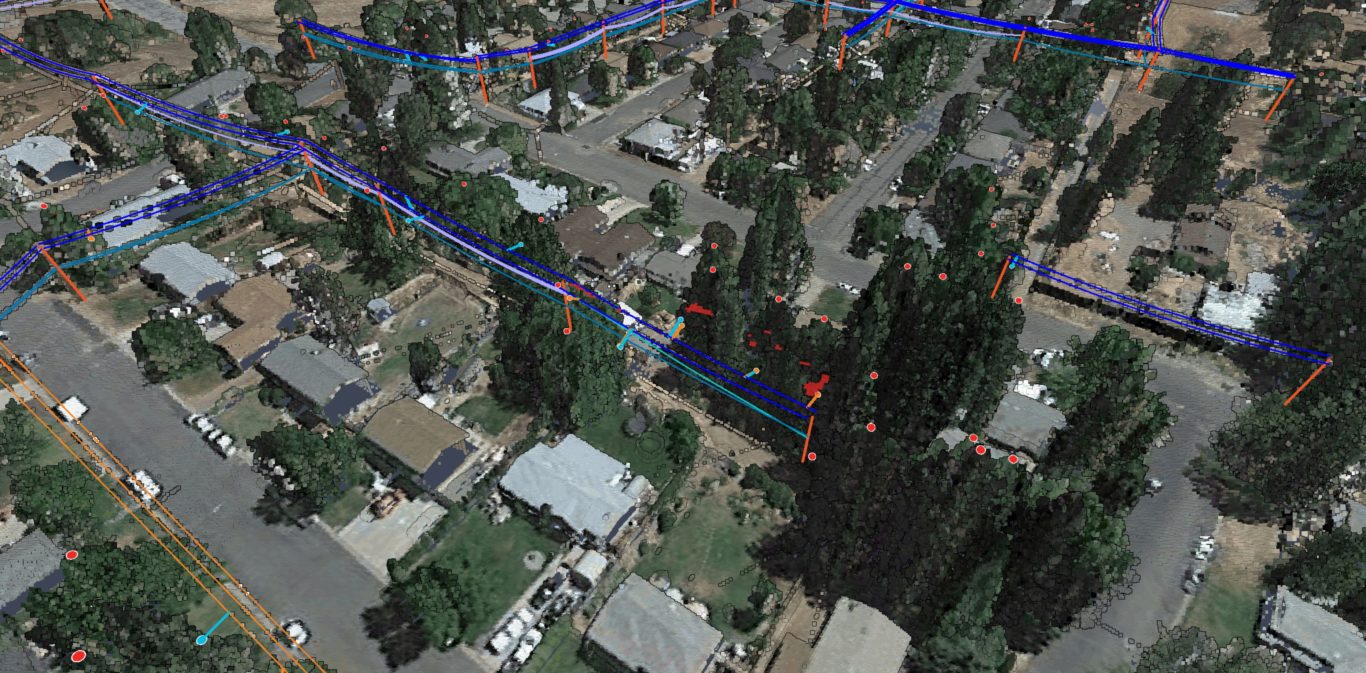

Sharper Shape is now helping clients carry out single-flight consolidated linear inspections, using helicopter cameras and sensors to simultaneously capture HD video, LiDAR (3-D data) and hyperspectral image data for the full length of a transmission or distribution line.

In recent years, advanced utilities have been augmenting their manual asset inspection programs with a data-rich approach. Once this data has been captured, it can be stored for later use on the cloud, allowing for an inspector to carry out a ‘virtual’ inspection at any time. Crucially, with shelter-in-place rules in effect, this can be done from anywhere with an internet connection, allowing power line inspectors to join the ranks of those who can work from home for the first time.

Of course, this does not negate the need for physical inspections entirely. However, it gives teams advanced situational awareness so that they can plan ahead based on the intelligence of what they will come across – for example, will they need a truck capable of elevating them 40 feet in the air, or 100?

Leaving behind the siloed data approach to asset management

What’s more, if this data is collected across the network (or a large portion of it), the utility benefits from a holistic asset condition assessment. This makes it possible to make better informed, more intelligent decisions on prioritizing areas and assets for inspection, thereby helping to ensure they get the best use out of a capacity-constrained workforce.

Finally, the utility can then use the LiDAR data to create 3-D flight plans to carry out fully automated inspection activities using aerial drones. This increases the efficiency of inspection teams by reducing the ground they need to cover – useful at any time, doubly so at a time of reduced manpower.

Ultimately it cannot be predicted how long the virus will continue to hinder operations, but history shows us that this is an agile industry well versed in responding and adapting to the challenges it faces. Sharper Shape’s Sharper Circle of Inspection Automation enables utilities to take a highly proactive approach to the rising inspection and operational challenges the face in these extraordinary times, helping utilities better understand their network and prioritize inspection programs.