Power companies today face an escalating level of environmental challenges and utility hazards. Data shows that wildfires, hurricanes and flooding are continuing to grow in severity. Between the Camp Fire in California last year and the Amazon fires this year, we have two recent reminders of just how quickly massive disasters can spring up out of nowhere and wreak havoc across entire communities.

Electric utility companies, among others, have a role to play in helping prevent or mitigate enviromental disasters ahead of time. With that, it has become evident that one of the major challenges in front of them is how to properly leverage data and associated analytics to accomplish this.

But that’s not an unsolvable problem. Power companies can embed new tools for not only collecting environmental data about their infrastructure and field assets but also organizing that data into workflows that can be leveraged for faster, intuitive and actionable means of forecasting and mitigating new environmental disasters. Time is of the essence here. These disasters are only getting worse; the next Camp or Amazon fire is a matter of “when,” not “if.”

The Data Challenges Facing Electric Utilities

Utility companies can only act based on the data they have and the maturity of the analytics tools to turn data into information. The ability to detect potential new environmental risks and react accordingly in moving the organization from reactive to proactive depends entirely on the data collected. Unfortunately, what we see too often today is that power companies are limited in the richness of data collected and the tools needed to turn descriptive analytics into prescriptive ones.

This circumstance is not unique to a small number of utilities but, rather, represents the current state of the industry as a whole. Utilities are operating power systems and grappling with challenges around asset data, geographic information system (GIS) accuracy and data resolution.

- Asset data: Utilities manage assets that run up to being decades old. That means they’re managing assets where data runs the gamut of being smart device-applicable to still existing on paper. Over the years, these power companies have adopted various data management systems to ingest data from analog to digital devices. These systems have also historically been designed to be transactional (i.e., maintenance order) rather than asset-designed (i.e., all data and transactions organized by the asset). Given that, asset data is often found in disparate systems based on different utility functions such as asset planning vs. vegetation management, which limits the utility’s overall understanding of total asset risks.

- GIS accuracy: The industry has made tremendous progress in adopting GIS tools and converting paper plat maps to GIS systems. Even with all this progress, however, many assets are simply not in correct locations, which can throw off analytics results among other operational challenges – such as replacing equipment on the wrong pole!

- Data resolution: The type of data being collected is maturing in both accuracy and precision. However, utilities still don’t have the sufficient data collection infrastructure needed to drive many business decisions made by deterministic data vs. probabilistic data. In this framework, a combination of sensor data and subject matter expertise data is used to support business decisions. The latter can be problematic due to the consistency – or rather, inconsistency – of how data is collected and how assessments are made.

Bridging Data Gaps with Aerial Platforms

Bridging Data Gaps with Aerial Platforms

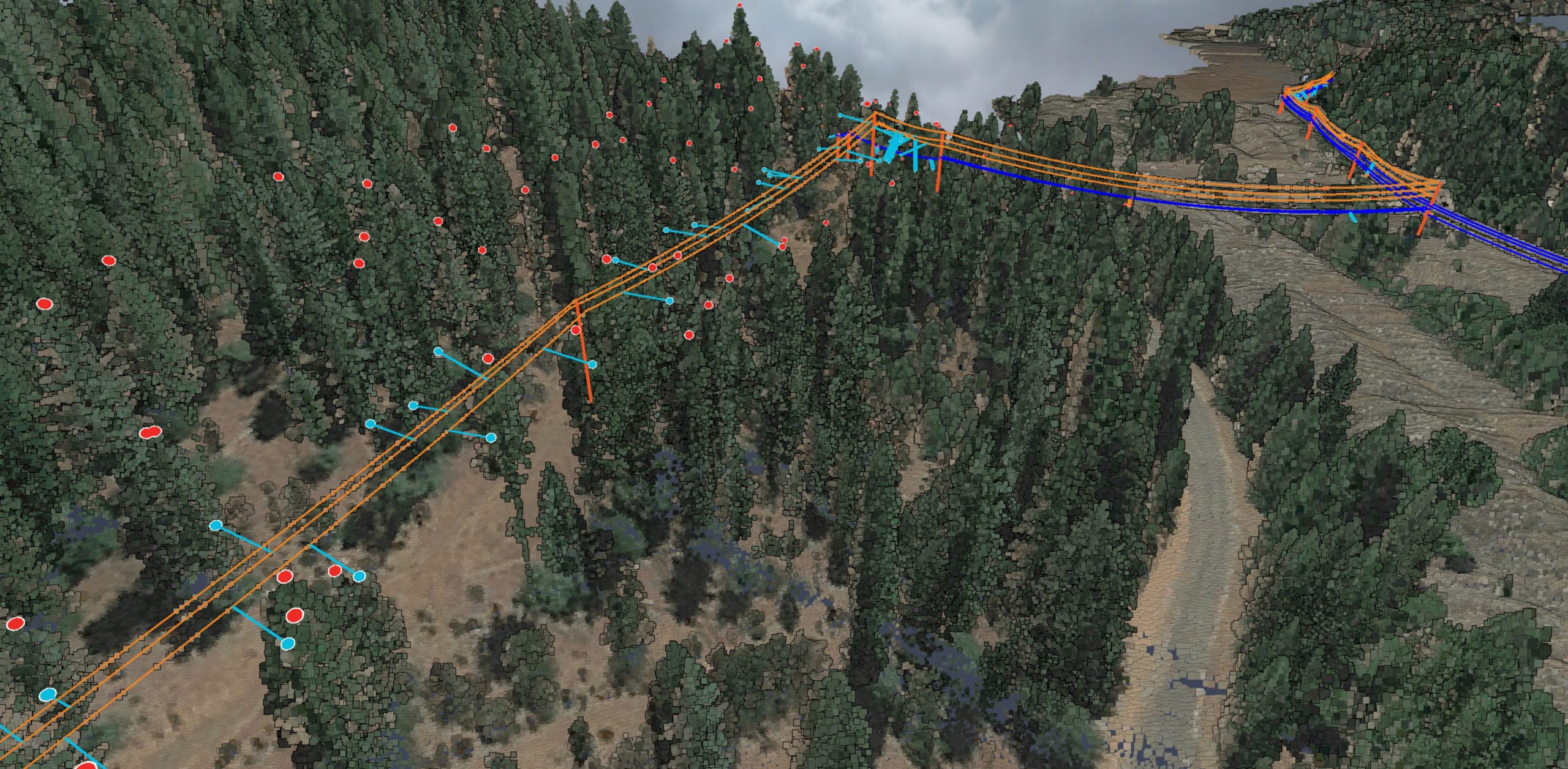

Sensor technology and aerial platforms, like drones, have come a long way, bringing new solutions to bear and helping the energy sector bridge some of its data gaps. Both manned and unmanned aerial alternatives to traditional utility asset inspections bring a number of distinct advantages to the table. Chief among those are the safety and cost benefits of bringing the asset to the inspector vs. bringing the inspector to the asset. But manned and unmanned aerial systems offer a slew of new data benefits, too.

High-resolution sensors capture an incredible amount of data for asset owners by providing closer proximities, a greater variety of angles and a wider range of acuity than you can otherwise achieve with human eyes. That data provides a more comprehensive picture of the asset, enabling a deeper assessment. This spans both detecting gross defects in a line or pole and minor defects that could someday mature into bigger problems. With this level of insight, power companies are able to nip potential problems in the bud before they become major, costly and potentially damaging issues down the road.

Aerial platforms also help to capture highly accurate geospatial data, which, in turn, helps improve GIS accuracy. Finally, inspection data stored within the cloud and shared across the entire organization – rather than being filtered through a particular lineman or field worker – creates a dynamic where everyone has an unvarnished look at the state of a particular asset. This can also help with developing business decisions that are based more on the data itself and less on the subjectivity of someone in the field. For example, collecting data in the cloud year over year, rather than siloing that data across disparate systems, helps to better enable change detection and predict equipment failures in the field.

What’s Next

Aerial platforms and data management suites comprising unique perspectives, easily traveled distances and objective evaluations already deliver tremendous value for power companies today. But this is just the tip of the iceberg;

The future boasts a lot of potential for how sensor technology and aerial platforms can help utilities de-risk the energy system and keep both the public and employees safe.

In the near term, that can mean everything from automating remote inspections via aerial platforms to leveraging collected data into various utility workflows, including estimating, pole loading, correcting GIS data, asset planning, emergency management and response, and so on. But over the long term, the possibilities for drone inspections run the gamut of beyond visual line of sight flights (pending widespread Federal Aviation Administration approval), leading to more frequent data captures; leveraging AI and machine learning algorithms to more quickly identify and remedy anomalies in aerial data collection; and automating inspections to accelerate how quickly data is delivered to workflow tickets and acted upon. These are just some of the enablers for utilities to move to a risk-based operating model leveraging prescriptive analytics.

Between last year’s Camp Fire, this year’s Amazon wildfires and the inevitable next major fire around the corner, concerns continue to rise about whether or not we’re doing everything possible to prevent the risk of man-made fires and other similar natural disasters, and rightly so. Many utility companies may already be aware of some of the potential uses or benefits of aerial systems, but the time has come for the industry as a whole to embed new technologies that de-risk their electric systems. The more power companies shift and adopt advanced data management systems, the more they will be equipped to identify hazards and risks along power lines or their environments – and ultimately stop would-be disasters.

Ilkka Hiidenheimo is the CEO of Grand Forks, N.D.-based Sharper Shape, a provider of drone-based automated inspections. He can be reached at ilkka.hiidenheimo@sharpershape.com.